0769-85317767

Products center

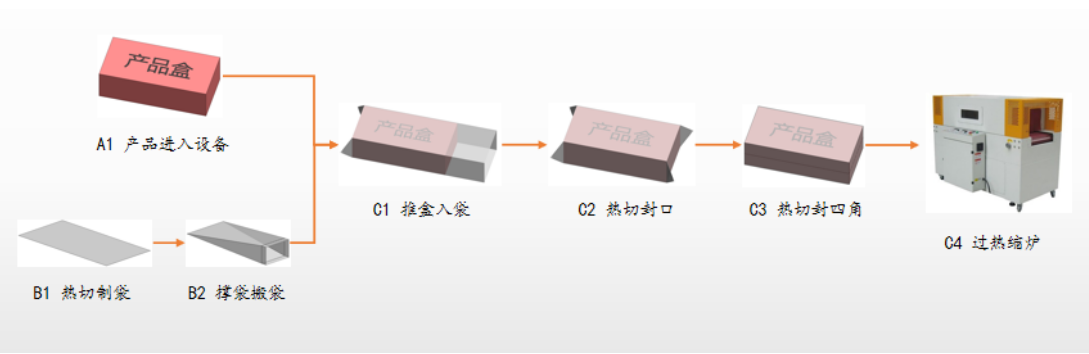

Equipment function

a. The equipment automatically packs POF shrink film on the surface of the product box. Because the POF shrink film has high transparency and good gloss, it can clearly display the product appearance, improve sensory awareness, and reflect high-end;

b. The equipment fully automatic packaging POF shrink film can ensure the consistency and reliability of packaging quality;

c. The equipment fully automatic packaging POF shrink film has faster speed and better quality than traditional manual packaging film, improves production efficiency, saves production costs, and improves company competitiveness;

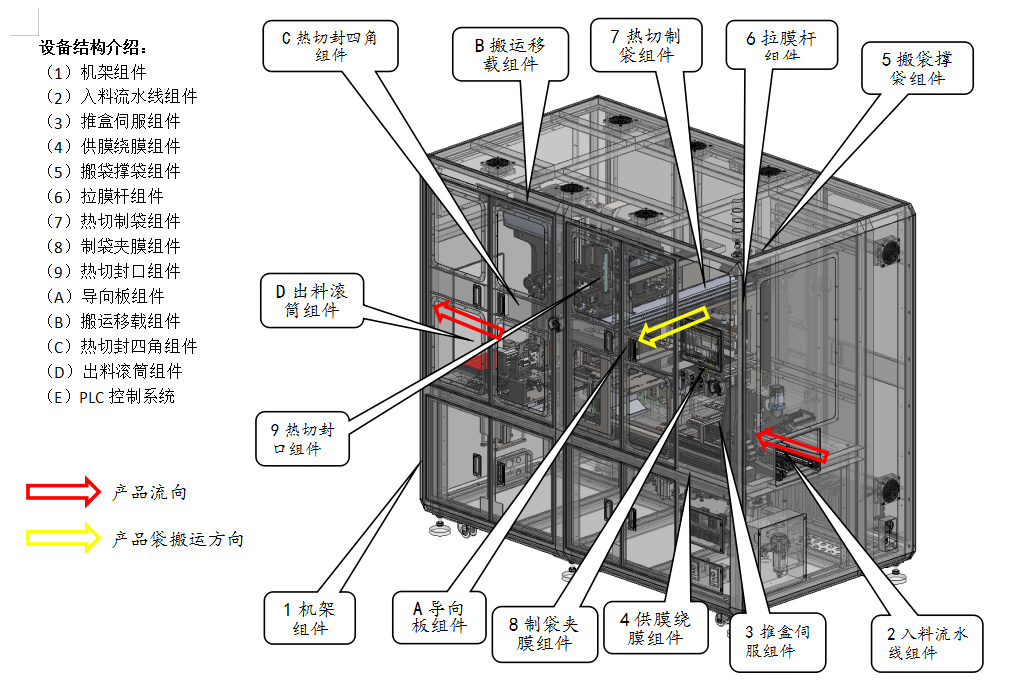

Equipment advantages

a. The appearance of the equipment adopts A3 paint + transparent acrylic, and the paint is beautiful and simple in white and black.

b. The equipment frame adopts 60 square-pass welding, and the equipment has high stability

c. The equipment servo sliding table adopts KK module and standard sliding table, with high repeat positioning accuracy

d. The equipment control system adopts Siemens PLC + Siemens servo motor, and the equipment system has high stability

e. The film releasing mechanism adopts an inflatable shaft, which is convenient to replace the POF film

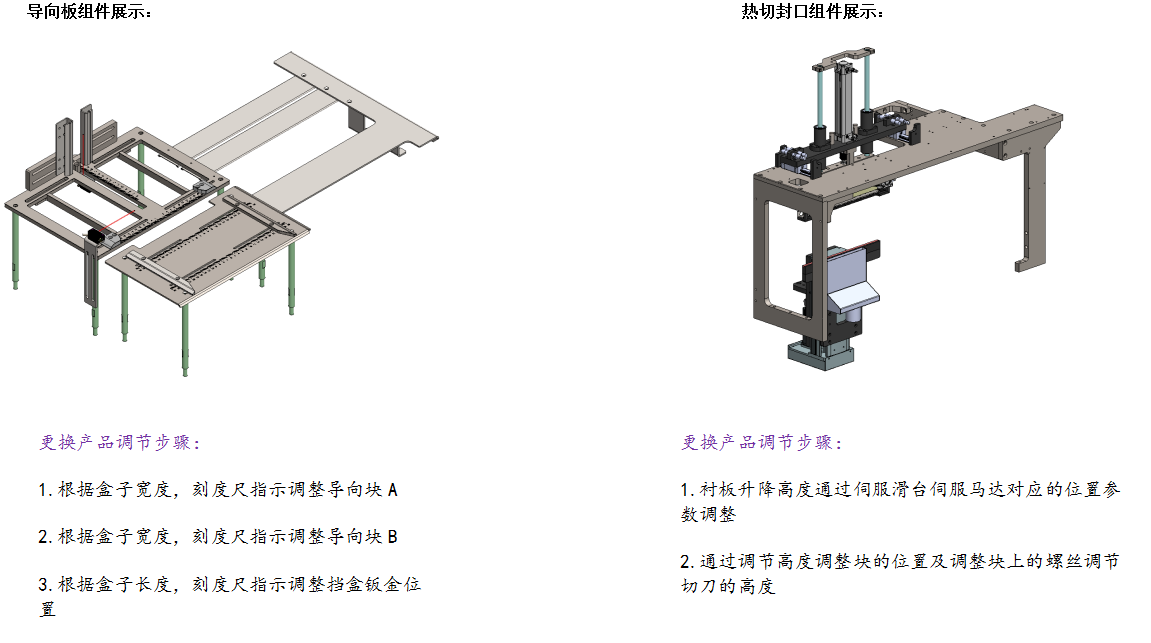

f. The equipment is universal within a certain range, and the adjustment mechanism adopts trapezoidal screw + wire rail + knob + scale, easy to change and adjust

g. The product parameter formula is set in the system, and the corresponding formula parameters can be directly called when changing the model, shortening the time for changing the model

h. The door used by the equipment adopts Omron safety door lock with high safety protection level

Equipment coating process

Device model | ZF02K | |||

Compatible production size

| L | 100mm~220mm | Working height | 850mm±50mm |

W | 70mm~220mm | power supply | Single phase AC220V 20A 50HZ | |

H | 30mm~100mm | Gas source | 0.5~0.7Mpa | |

UPH | 500Pcs~650Pcs (UPH is determined according to product size) | weight | about 1300Kg | |

Product yield | ≥ 98% | Dimensions | 2200mm(L) x 1240mm(W) x 1850mm(H) | |

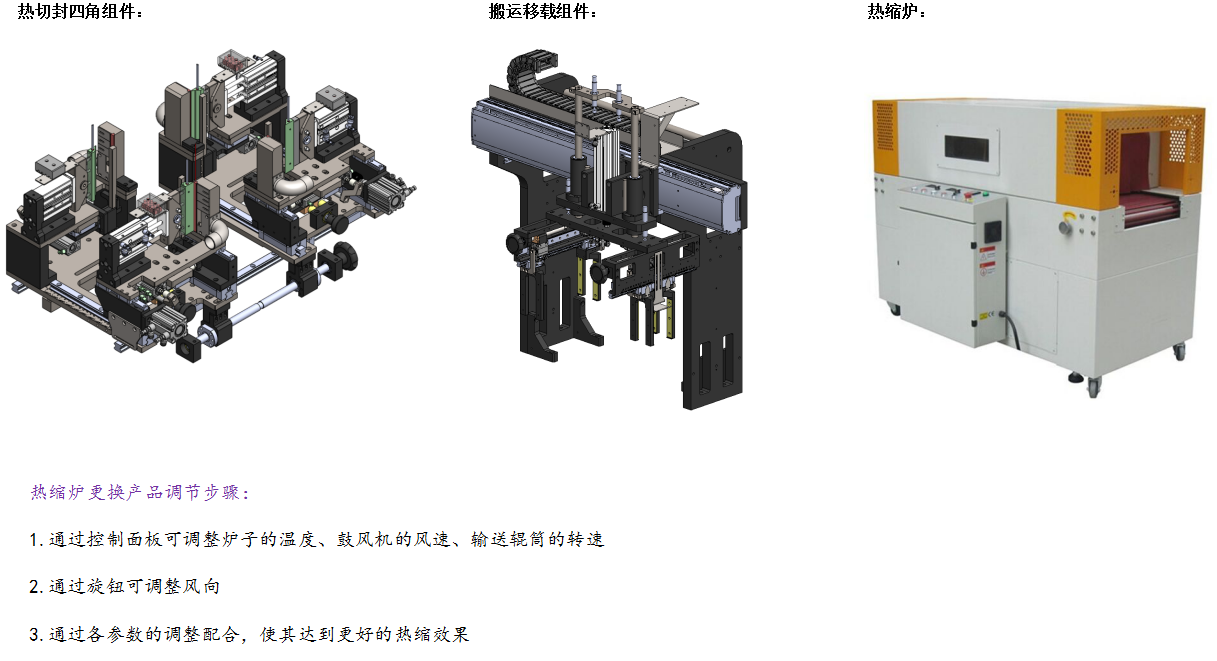

Remarks: The overall dimensions of the heat shrinkable furnace [1800mm(L) x 980mm(W) x 1280mm(H)], the specific dimensions of the equipment are subject to the actual product

Serial number

| Configuration table of key equipment components | |||

Key component name | Brand | Remarks | |

1 | frame | / | Fangtong welding frame, sheet metal shell and transparent acrylic window |

2 | Cutter, liner | / | SKD11 material cutter, covered with high temperature resistant rubber liner |

3 | Screw rod, linear rail | HIWIN | |

4 | Cylinder, solenoid valve, quick connector | AIRTAC | |

5 | Magnetic switch, photoelectric sensor | OMRON/Panasonic | Use OMRON plug-in magnetic switch to improve equipment safety level |

6 | Servo motor, PLC | Siemens/Mitsubishi | |

7 | Operation panel | Weiluntong | |

Company:Dongguan Zhibang Electronics Co. LTD

Adrress:Floor 15, Yuchang Building, No. 15, Dongyi Lane, Zhongfu Street, Shaguan District, Changan Town, Dongguan City

South China Sales Company: Chengdu Xuanxiang Technology Co., Ltd

Company Address: Room 34F02, Building 2, Shudu Center, Tianfu Second Street, High tech Zone, Chengdu City

Phone: 028-83223255

Fax: 028-8322010

Copyright 2021 Dongguan Zhibang Electronics Co. LTD All rights reserved 粤ICP备14008616号