0769-85317767

Products center

.Wide temperature measurement range: 50 to 3200 °C

.Distance factor ratio (optical resolution) up to 300:1

.The spot area is as small as 0.6mm, capable of measuring small target objects

.Response time is only 2ms

.Manual focus option for easy installation

.Various aiming methods, visual aiming, video aiming, LED or laser aiming options

.The stainless steel housing with protection grade IP65 (NEMA 4) can withstand ambient temperature up to 65℃

.Multiple communication interfaces (RS-485, Ethernet, Profinet) for easy access to network server, Ethernet ASCII and video streaming

.Programmable relay output

.Analog and digital synchronous output

Features of SpotScan:

· Durable IP65 housing can withstand ambient temperatures up to 60℃

· Degas option can be used in dusty or dirty environment

· Use the on-board sensor to achieve aiming via laser (through lens aiming), LED or video function

Features of ThermoJacket:

· Rugged cast aluminum housing can withstand ambient temperatures up to 315℃

· Mechanical/thermal environmental protection

· Air/water cooling and lens dust removal in one

High temperature heat treatment

Heat treatment is a process used to change the physical properties of metals. The heat treatment process includes annealing, hardening, normalizing, quenching, tempering and strengthening.

In metal processing, hot rolling is a metal forming process that refers to rolling above the metal recrystallization temperature. The hot rolling process includes preheating furnace, descaling machine, slab scale, roughing mill, finishing mill and cooling line. After the steel billet is heated, it is usually heated in a secondary heating furnace. When the temperature of the raw material is raised to a suitable temperature, it is rolled with a roller to obtain the desired metal properties.

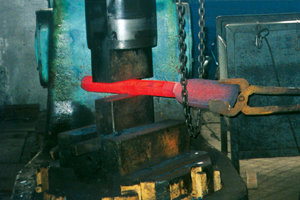

Forging is a process in which the pressure between two tools is used to transform metals or alloys. For example, hot forging of steel at 950-1250°C, warm forging at 750-950°C, and cold forging at 150°C. The metal blank is heated. The heating method can be electric furnace heating, induction heating, etc., infrared thermometers are used to measure the hot forging, forging, and heating temperature before forging of hot steel, brass, bar and other forgings in a non-contact manner. Non-contact infrared thermometers are often the recommended temperature measurement method for reasons such as unfixed position or irregular shape of the workpiece. The temperature data measured by the thermometer can be uploaded to the upper computer such as a display meter or a data logger to meet the needs of field operators for monitoring or data storage at any time.

In the foundry, molten metal is poured into molds. Remove the mold material or casting after the metal has solidified. Typical casting applications include sand casting, investment casting, die casting and billet (ingot) continuous casting. In these casting processes, temperature is a very critical parameter. For example, pouring temperature, die-casting mold temperature, casting surface temperature, these indicators have a great impact on casting production.

Company:Dongguan Zhibang Electronics Co. LTD

Adrress:Floor 15, Yuchang Building, No. 15, Dongyi Lane, Zhongfu Street, Shaguan District, Changan Town, Dongguan City

South China Sales Company: Chengdu Xuanxiang Technology Co., Ltd

Company Address: Room 34F02, Building 2, Shudu Center, Tianfu Second Street, High tech Zone, Chengdu City

Phone: 028-83223255

Fax: 028-8322010

Copyright 2021 Dongguan Zhibang Electronics Co. LTD All rights reserved 粤ICP备14008616号