0769-85317767

Products center

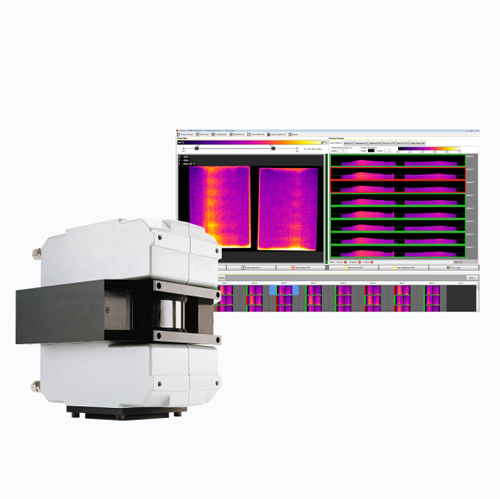

.Full set of industrialized design software and hardware system

.The software is easy to use, the view is clear at a glance

.Meticulous and continuous quality monitoring of gypsum board

.Real-time detection of blistering, underskin and clots

.Query fault and tracking function in database

.Automatically identify defective boards in real time

.History database LogViewer can be used as a quality management tool

.High-resolution thermal imaging camera can obtain accurate infrared images

.Complete hardware system configuration can cope with harsh field environment

.Networking function facilitates remote communication

.Configure TIP900 system on site and train operators

.Accuracy: ±2% of measured value or ±2℃, whichever is greater

.Temperature range: 350 ºC max.

.Ambient temperature: 0 – 50 °C

The TIP900 system is a comprehensive thermal imaging and non-contact profile analysis system designed to monitor the temperature of the oven wall. It uses an infrared thermal imager to continuously scan the surface temperature of the entire board, and can detect the moisture and density changes inside each board in real time.

The powerful TIP900 software can provide complex data integration, visualization and event analysis, and provide users with a complete solution for real-time monitoring, detection and traceability. It also analyzes and provides the best oven dryer profile balance.

Detailed wallboard quality graphs, historical temperature trend graphs and images can be viewed locally or remotely on the operator workstation. All data is stored in the LogViewer database to achieve complete process visibility and long-term traceability.

TIP900 system software

· Detailed continuous circuit board quality monitoring (100% of all circuit board images are archived)

· Simple recipe setting-automatic scaling

· Automated board defect detection and rejection

· Ethernet connection: process data, defect reports, dryer balance configuration files, etc. can be shared with HMI/SCADA

· Dynamic deck-to-deck dryer contour balance monitoring

· Fault identification function tracked in the database

· Database LogViewer for historical analysis (for remote access to any TIP900 on the company network)

· Configurable rejection/alarm parameters

Gypsum wallboard production

Wallboard is made of natural gypsum (calcium sulfate) extracted from coal-fired power plants or the so-called by-product gypsum calcium sulfate. The raw materials are mixed with water and additives. The mixture called "slurry" is spread on the moving paper. During the entire process of the production line, it solidifies and is finally cut to the required length, then the boards enter the dryer. Monitor the drying process to prevent voids and cracks in the wall panels.

Company:Dongguan Zhibang Electronics Co. LTD

Adrress:Floor 15, Yuchang Building, No. 15, Dongyi Lane, Zhongfu Street, Shaguan District, Changan Town, Dongguan City

South China Sales Company: Chengdu Xuanxiang Technology Co., Ltd

Company Address: Room 34F02, Building 2, Shudu Center, Tianfu Second Street, High tech Zone, Chengdu City

Phone: 028-83223255

Fax: 028-8322010

Copyright 2021 Dongguan Zhibang Electronics Co. LTD All rights reserved 粤ICP备14008616号