0769-85317767

Products center

. Improve efficiency and product quality

.Reduce installation time and scrap rate

.Quickly detect defects and heating element failures

.Automated quality monitoring

.View the complete thermal image and temperature distribution

.Define specific product configuration and data files

.Customize the thermal image of the display area

.Automatic analysis of regional temperature

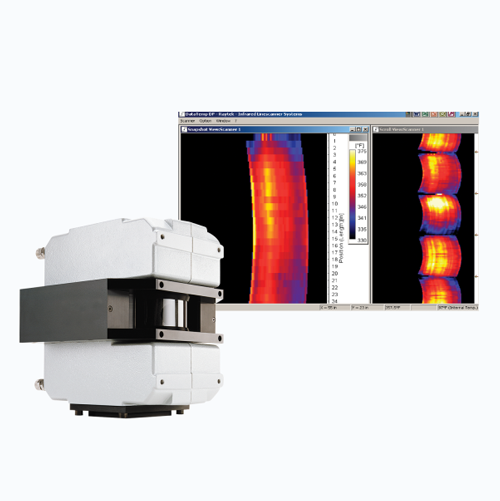

The TF150 thermal imaging system can help us measure the temperature distribution of the processed plastic parts and visualize the thermoplastic molding process.

The TF150 system has an easy-to-use, "click to focus" human-computer interaction interface. It is easy to install and is installed above the gap between the outlet of the heating furnace and the forming press. After connecting the cable to the control computer, and entering the installation size in the tf150 software, this simple installation process is completed

The software displays the temperature of each area defined by the customer and stores a snapshot of the thermal image of each product passing through the area. Can display 100 areas (some of them contain alarm conditions. High temperature alarms are displayed in red, low temperature alarms are displayed in blue. These results can be output to your PLC or SCADA system. The software can ignore the test part of the thermal image (background) The temperature of the area.

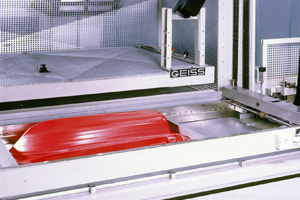

In the thermoforming process, one or more plastic sheets need to be heated to a temperature suitable for forming or stretching in or on the mold, and then taken out, trimmed and cooled. The finished products include disposable cups, large single-piece car body covers, etc. The process can be semi-continuous (as a thin plate fed from a roller) or discontinuous (heavy single large plate).

· Equipped with a variety of optional output methods (OPC; ASCII; analog; alarm signal, etc.) and easy to operate and flexible configuration software, which can output a complete temperature image;

· It is a unique solution for temperature monitoring of continuous hot pressing process;

· The thermal image of each single-chip product can be viewed on other terminals in the same company network

Company:Dongguan Zhibang Electronics Co. LTD

Adrress:Floor 15, Yuchang Building, No. 15, Dongyi Lane, Zhongfu Street, Shaguan District, Changan Town, Dongguan City

South China Sales Company: Chengdu Xuanxiang Technology Co., Ltd

Company Address: Room 34F02, Building 2, Shudu Center, Tianfu Second Street, High tech Zone, Chengdu City

Phone: 028-83223255

Fax: 028-8322010

Copyright 2021 Dongguan Zhibang Electronics Co. LTD All rights reserved 粤ICP备14008616号