0769-85317767

Products center

. Improve efficiency and product quality

.Reduce installation time and quickly detect defects

.Verify the production process configuration and data files of the product

.Automated ISO9000 quality monitoring

.View the complete thermal image and temperature distribution

.Customize and display the area covered on the thermal image

.Automatically analyze the temperature of key areas

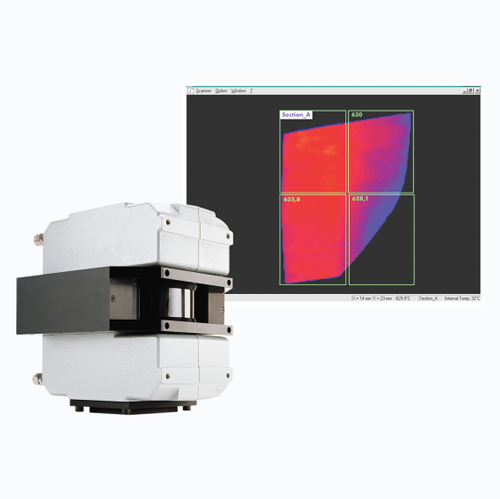

GS150 thermal imaging system is an automatic temperature measurement system, suitable for measuring glass bending, forming, annealing and tempering processes. GS150 scans a 90º field of view angle through a rotating mirror, up to 150 times per second, and up to 1024 points per line. The start of temperature measurement can be triggered by the target entering the field of view or by an external "trigger" signal. When each heated glass passes through the scanning area, a two-dimensional thermal image or "thermal image" will be recorded and displayed.

GS150 is easy to install, just like installing a camera, as long as there is an unobstructed path, the glass can be seen from above. Connect the pre-connected cable (shipped randomly) to the PC, and enter the installation dimensions in the GS150 software to complete the installation process.

GS150 software

The GS150 thermal imaging system allows you to see what happens during the glass manufacturing process. The divided grid represents the element heating area in the furnace. The average temperature of each area is displayed in the corner of the system. Each application will set a unique area based on different heater sizes and locations. The temperature of each zone is displayed as average, maximum, or minimum. Can be configured serial or analog to provide an output signal that matches the temperature of each zone. Thermal image data files will be stored for subsequent analysis and display. When the cursor moves to the selected position around the thermal image, the spot temperature and position (x and y coordinates) will appear on the taskbar. Move the cursor to the selected point, the software will display the corresponding temperature distribution at the point where the machine direction and the cross machine direction intersect.

GS150LE low emissivity glass thermal imaging system (Low-E)

The GS150LE low-emissivity glass thermal imaging system (Low-E) is based on the mature Raytek GS150 system and is specifically designed for monitoring and optimizing the tempering process of flat glass coated with a low-reflection coating on one side.

The system has an automatic emissivity correction mode, which can adjust the changes between different glass varieties. It allows users to set up predefined methods to adapt to frequent product changes.

By quickly detecting thermal anomalies inside the glass and identifying defective heating elements, GS150LE can help glass processing plants improve product quality and consistency, and reduce waste.

· View the complete heat map and temperature profile

· Thermal image "snapshot" obtained after temperature or external triggering

· Automatic analysis of regional temperature distribution (minimum, maximum, average, gradient, etc.)

· Fail safe alarm record

· Define product-specific configurations (recipes)

· Event-based thermal image saving and archiving function for analyzing temperature data

· Simple connection with existing visualization and control system through flexible system interface: OPC or DDE, analog or digital output module, serial RS232 port, Ethernet

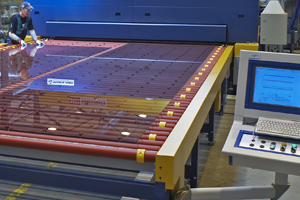

The tempering of flat glass is achieved by heating and quenching in a continuous furnace or a reciprocating furnace. This process is usually carried out in two separate chambers, and the quenching is carried out with a large amount of air flow. This application can be a low-mix or low-mix large volume.

Float glass is a glass plate made of molten glass floating on a bed of molten metal (usually tin). The advantages are uniform thickness and smooth surface. After leaving the tin bath, the glass plate passes through the cooling furnace and gradually cools, so that it is annealed without strain and will not crack due to temperature changes.

This application involves sag-bending forming of windshields for cars and trucks/buses. The glass plate is heated until it enters the viscoelastic phase, and then the glass is dropped into the forming machine to form the desired shape.

Company:Dongguan Zhibang Electronics Co. LTD

Adrress:Floor 15, Yuchang Building, No. 15, Dongyi Lane, Zhongfu Street, Shaguan District, Changan Town, Dongguan City

South China Sales Company: Chengdu Xuanxiang Technology Co., Ltd

Company Address: Room 34F02, Building 2, Shudu Center, Tianfu Second Street, High tech Zone, Chengdu City

Phone: 028-83223255

Fax: 028-8322010

Copyright 2021 Dongguan Zhibang Electronics Co. LTD All rights reserved 粤ICP备14008616号