0769-85317767

Products center

.Using the film temperature curve can more effectively control the cooling roll

. Early detection of mold bolt heater problems or blockage of mold

.Define product-specific configuration and data files

.View the complete sheet temperature profile for more effective cold roll control

.Define product-specific configuration and data files

.Customize and display the area covered on the thermal image

.Automatically analyze the temperature of key areas

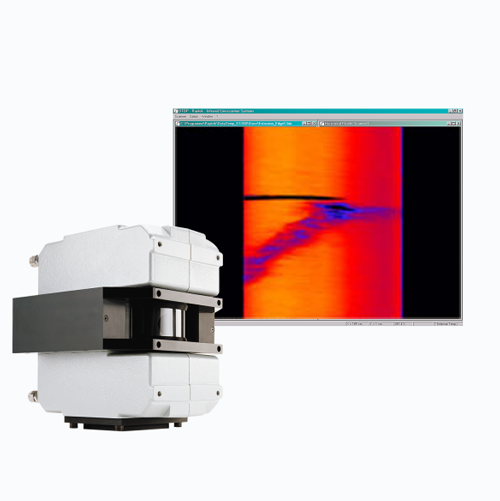

The ES150 sheet extrusion process imaging system is an automatic detection system for detecting, measuring and analyzing defects that occur in the process of single sheet extrusion, cast film and woven mesh. The ES150 system continuously monitors the entire process and converts temperature data into visual graphs (cross-sectional temperature) and thermal images. The measured files and images can be printed or archived for future analysis.

By using OPC (OLE for Process Control, the es150 system can be used as an OPC server and communicate with many commonly used process control systems. This feature allows ES150 to go beyond just a measurement tool and become an integral part of the entire process control system. section.

The ES150 system has the ability to define and read the corresponding temperature data of the plate in a specific area. The sector is defined by the name, location, and temperature data to be processed within the sector (for example, average, minimum, or maximum temperature).

This function is very useful for sheet extrusion and cast film extrusion processes. Sectors can be configured to provide a temperature corresponding to each die bolt heater. In the event of an alarm, the information is automatically saved, indicating the time, alarm duration and defect location. When the alarm is triggered, 500 temperature lines are automatically stored in the alarm log file.

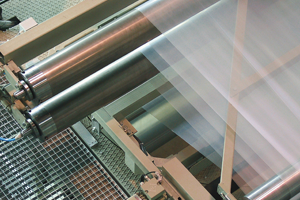

Plastic sheet extrusion:

In the plastic sheet extrusion process, the polymer melts and passes through (extrudes) a slit/flat die to form a molten sheet. The plate is attracted to the surface of the cooling roll and immediately solidifies. The board then passes through a series of rollers to determine its thickness and texture, then trims its edges and cuts it to the required size (heavy board) or rolls it onto rollers (thin board). The extruded plastic sheet is often thermoformed into the final shape (such as in the manufacture of refrigerator or freezer interior panels or plastic beverage cups).

In the production of cast film, the polymer melts and traverses (extrudes) through a slot or flat die to form a molten film. The film is attracted to the surface of the cooling roll by the force of the air knife or vacuum box and immediately solidifies. The film then passes through a series of cooling rolls and edge trimming before being rolled onto a roll. Some machines also extrude multiple films to laminate them into the final product.

The continuous process laminating and embossing machine usually heats and cures multiple substrates at the same time, and then emboss the texture to one or both sides. According to the finishing requirements, a calender roller can also be used to trim the surface gloss, smoothness and thickness uniformity. Heating rollers and electric or gas infrared panel heaters are used to increase the heat energy in the process.

During the process, the molten polymer tube (usually polyethylene) extruded from the die is inflated several times to form film tubular bubbles. The air bubbles gradually cool down when they are pulled up until they solidify, and then are rolled up and cut into flat films or made into plastic bags before they collapse. Solidification occurs on the cooling line, and the location of the cooling line is subject to parameters such as airflow, speed, and ambient temperature difference.

Company:Dongguan Zhibang Electronics Co. LTD

Adrress:Floor 15, Yuchang Building, No. 15, Dongyi Lane, Zhongfu Street, Shaguan District, Changan Town, Dongguan City

South China Sales Company: Chengdu Xuanxiang Technology Co., Ltd

Company Address: Room 34F02, Building 2, Shudu Center, Tianfu Second Street, High tech Zone, Chengdu City

Phone: 028-83223255

Fax: 028-8322010

Copyright 2021 Dongguan Zhibang Electronics Co. LTD All rights reserved 粤ICP备14008616号