0769-85317767

Products center

.Fast, automatic detection of undulations or moving edges, gaps and tearing edges

.Ensure proper web temperature to achieve strong film and substrate bonding

. Improve profitability and product quality

.Define product-specific configuration and data files

.View the complete thermal image and temperature curve

.Customize and display the area covered on the thermal image

.Automatic analysis of regional temperature

.Optional analog or digital output

.Fail safe alarm record

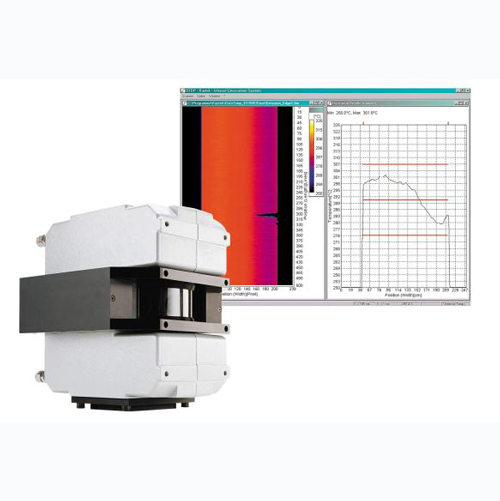

The EC150 thermal imaging system is an automated surface inspection system used to detect, measure and classify defects in extrusion coating, co-extrusion and lamination processes. This system provides a unique function for managing the quality of the plastic film extrusion process.

Over the entire width of the flow channel of the extruder, temperature and viscosity changes in the local melt flow can cause "waves". Or "running" edges, gaps and edges tear in the extruded film. The EC150 system uses the MP150 Process Imager to continuously monitor the temperature distribution and width of the extruded melt curtain to automatically detect such defects.

EC150 extrusion system software

The EC150 system monitors the extrusion process to display temperature data as line graphs (contours) and thermal imaging images. Personal data and images can be printed or archived for future analysis.

Automatic edge detection

This automatic fan function unique to EC150 can continuously monitor the melt curtain from the extruder die and provide automatic edge detection. The automatic sector is suitable for measuring plastic sheets of different widths. Temperature differences, unacceptable fluctuations, edge running or edge tearing can be detected immediately, and if a malfunction or defect occurs, an alarm will be triggered to take quick corrective actions.

Extrusion coating

The processes of extrusion coating (on top of the substrate) and extrusion lamination (between two substrates) similarly press the molten thermoplastic resin onto a moving web through a horizontal die. Substrates include paper, aluminum, cards and printing films.

Company:Dongguan Zhibang Electronics Co. LTD

Adrress:Floor 15, Yuchang Building, No. 15, Dongyi Lane, Zhongfu Street, Shaguan District, Changan Town, Dongguan City

South China Sales Company: Chengdu Xuanxiang Technology Co., Ltd

Company Address: Room 34F02, Building 2, Shudu Center, Tianfu Second Street, High tech Zone, Chengdu City

Phone: 028-83223255

Fax: 028-8322010

Copyright 2021 Dongguan Zhibang Electronics Co. LTD All rights reserved 粤ICP备14008616号