0769-85317767

Products center

.Integrated thermal imaging system detects kiln hot spots caused by loss, damage or wear of refractory materials

. Delineate the entire kiln surface and display the thermal image in real time

. Early recognition of abnormal operation, such as incorrect flame position and shape

.Extend the service life of furnaces and refractories

.Integrated monitoring of key parameters of the furnace

.3D imaging and refractory management software supports up to 4 scanning thermometers

.The resolution of hot spot detection in the shadow area can reach "a brick" accuracy

.Fail safe "over-temperature point" alarm output (no computer required)

.Communicate with other programs through OPC

.Reliable optical fiber communication to prevent electrical interference (lightning, grounding or EMI issues)

.Modular design simplifies installation and service

.Multi-level security settings"

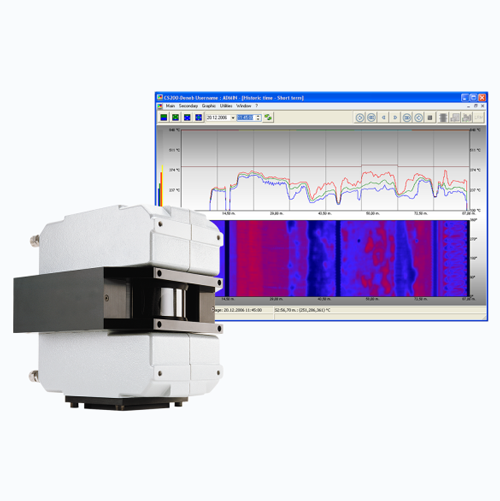

The CS210 rotary kiln thermal imaging system is a comprehensive monitoring system that can detect hot spots on the rotary kiln, thereby avoiding costly equipment damage and reducing unplanned downtime. With multiple optional functions, and can be fully integrated display, including shadow sensing, combustion zone monitoring, tire slip, fan control, refractory material management and three-dimensional real-time view.

The temperature of the kiln body of the rotary kiln is monitored along the entire length of the kiln to provide a basic indication of the refractory condition. The temperature data of the "shadow" area provided by the spot thermometer can be provided to a scanner by up to 4 single-point sensors, and seamlessly integrated into a complete thermal image. Optional combustion zone and tire slip monitoring can be integrated into the thermal imaging system, so that all information is displayed on a screen in the control room, and all abnormal event data will be stored in a common historical data database.

With all the options and accessories, the cs210 system is expanded into a comprehensive furnace monitoring tool.

The easy-to-understand Windows® Datatemp CS210 software provides simple configuration and startup functions. The CS210 system software can be run on an ordinary computer, and data transmission uses a standard Ethernet or COM port. The graphical user interface is specially designed for the kiln application. Because of its simple setting and use, it requires little training for the operator to be proficient in use. The three-dimensional view and refractory management software options enable the kiln and refractories to be controlled and tracked through an integrated refractory management database, and visualized through a friendly, easy-to-understand, real-time three-dimensional view.

In order to ensure that the MP150 line scanner can operate reliably in harsh environments, in the design of the CS210 thermal imaging system, the scanner uses a solid cast aluminum housing and a stainless steel protective box installed on site. The protective box includes an adjustable mounting bracket to align the scanner along the axis of the rotary kiln. The mounting rail allows quick disassembly and assembly of the scanner, quick disconnection of air purification and water cooling accessories, and an easy-to-replace observation window.

Infrared monitoring of cement processing kiln shell temperature

The rotary kiln used for cement processing is made of steel and lined with ceramic refractories to protect the steel from the heat of the burner (1500°C).

Company:Dongguan Zhibang Electronics Co. LTD

Adrress:Floor 15, Yuchang Building, No. 15, Dongyi Lane, Zhongfu Street, Shaguan District, Changan Town, Dongguan City

South China Sales Company: Chengdu Xuanxiang Technology Co., Ltd

Company Address: Room 34F02, Building 2, Shudu Center, Tianfu Second Street, High tech Zone, Chengdu City

Phone: 028-83223255

Fax: 028-8322010

Copyright 2021 Dongguan Zhibang Electronics Co. LTD All rights reserved 粤ICP备14008616号