0769-85317767

Products center

Introduction

IntroductionThe peristaltic glue dispenser is also called the precision glue dispenser, because it can precisely control the amount of glue output, and it is also a device used to dispense instant glue. Due to the nature of the glue, the equipment is different from the traditional dispenser equipment in terms of material. Partial parts made of special Teflon tube are used, which effectively avoids the problem of glue blockage and is ideal for dispensing Craft.

Scope of application

Scope of applicationAnaerobic glue, instant adhesive, flux, silicone oil, thread glue, solvent, ink, paint, UV glue and light curing glue.

Features

FeaturesTime controls the amount of glue, with high repeatability and stability.

It is convenient to switch between forward and reverse and has good self-priming ability.

The pipeline installation is convenient, the fluid does not touch the pump body, and there is no pollution.

Suitable for low-viscosity glue, the viscosity is generally below 5000CPS.

Without external air pressure, the liquid is directly sucked and the liquid is delivered through the rotor part.

Device parameters

Device parametersmodel | QUICK 984SZB |

power supply | AC220V(±10%) 50/60Hz |

Power consumption | ≤40W

|

Glue viscosity | <5000cps |

range of rotation | 0.1-180rpm |

Speed resolution | 0.1rpm |

Adjustment method | button |

Display method | 1.8寸TFTColor screen |

control | Button or external switch |

working environment | Ambient temperature 0~50℃, relative humidity <80% |

Dimensions | Dimensions90mm*240mm*180 |

Principle explanation

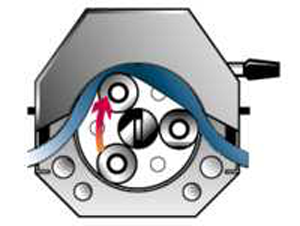

Principle explanationStructural principle: The peristaltic pump head is divided into two parts: the rotor and the pump casing. The pump tube is fixedly placed between the rotor and the pump casing, and the runner compresses the pump tube in the pump.

Movement principle: The motor drives the rotating shaft to rotate, and the runner on the rotor runs over the pump tube in turn, pushing the fluid in the tube forward. The pump tube after the runner runs back to its original shape due to its own elasticity, and a vacuum negative pressure is formed at the suction end of the pump tube, and the liquid is sucked in due to the vacuum negative pressure, so that the dispensing operation is performed.

Company:Dongguan Zhibang Electronics Co. LTD

Adrress:Floor 15, Yuchang Building, No. 15, Dongyi Lane, Zhongfu Street, Shaguan District, Changan Town, Dongguan City

South China Sales Company: Chengdu Xuanxiang Technology Co., Ltd

Company Address: Room 34F02, Building 2, Shudu Center, Tianfu Second Street, High tech Zone, Chengdu City

Phone: 028-83223255

Fax: 028-8322010

Copyright 2021 Dongguan Zhibang Electronics Co. LTD All rights reserved 粤ICP备14008616号