0769-85317767

Products center

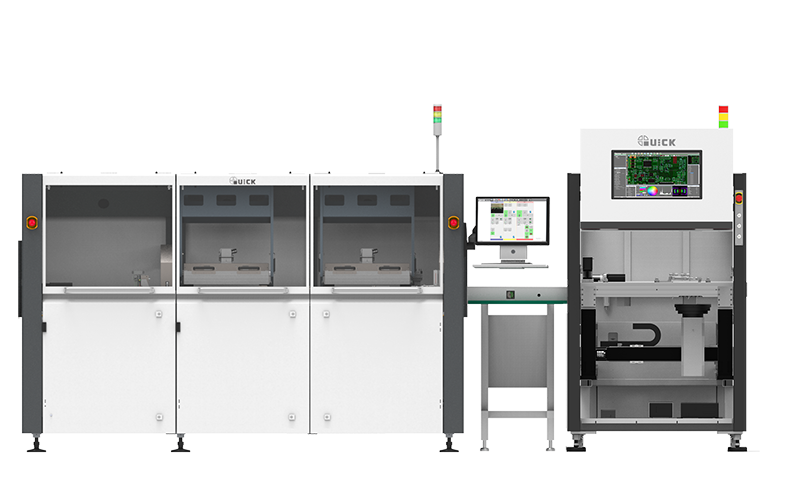

● Modular design, strong expandability of equipment.

● High efficiency, energy saving, high-end quality.

● High reliability, precision and repeatability.

● It can weld PCB with size up to 510x510mm.

● Self-developed operation control software, easy to understand.

● Support multiple programming methods such as GERBER files, JPG files, and CAD files.

● Unique visual graphical programming, more convenient.

Module

Module

|

Flux Module● Single-head spraying or double-head spraying (optional) can be used. ● Imported high-precision injection valve with a nozzle diameter of 0.178mm. ● Flux spraying XY axis positioning accuracy ≤±0.05mm. ● Flux spraying supports atomization and drip spraying. ● Flux storage level monitoring. |

Preheat module● The preheating station adopts the upper hot air and lower infrared method, which can be switched up and down at any time according to the process technology. ● The upper and lower preheating can open the heating tubes in different areas according to the size of the PCB board, heating and temperature control in different areas. ● Preheating temperature range: 0-200℃, temperature control accuracy is ±2℃. ● The welding station can also be equipped with upper hot air preheating, which can ensure the preheating temperature during the entire welding process. Improve welding quality. |

|

|

Welding module

● The wave height is ≤5mm, and the soldering temperature is ≤320℃. ● The soldering tin level is automatically monitored, when the soldering tin level drops to the set value, it can give an alarm. ● The nozzle and the base are connected by a magnetic system, which can quickly replace the nozzle. ● Visual camera monitoring of welding process, equipped with lighting and camera system. ● Double cylinder adjustment distance 80-169mm (effective when matching). |

Device parameters

Device parametersMachine parameters | model | EL9W5050ZD1A | EL9W6060ZD1A |

MaxPCBBoard size | 510*510mm | 610*610mm | |

MinPCBBoard size | 120*70mm | 120*70mm | |

PCBTop clearance | 120mm | 120mm | |

PCBTop clearance | 60mm | 60mm | |

PCBTop clearance | 4mm | 4mm | |

Height of conveyor belt from ground | 900±50mm | 900±50mm | |

Track widening range | 70-510mm | 70-610mm | |

Dimensions | 2700*1800*1700mm | 3000*1800*1700mm | |

Flux system | Jet height | 60mm | 60mm |

Positioning speed | ≤800mm/s | ≤800mm/s | |

positioning accuracy | 士0.05mm | 士0.05mm | |

Flux tank capacity | 2L | 2L | |

Preheating system | Preheat temperature range | 0-200℃ | 0-200℃ |

Preheating temperature control accuracy | ±2℃ | ±2℃ | |

Bottom preheating | 12KW(Infrared) | 15KW(Infrared) | |

Top preheat | 5KW(Hot air) | 5KW(Hot air) | |

Welding system | Max wave height | 5mm | 5mm |

Tin furnace capacity (single tin furnace) | 13kg | 13kg | |

Max welding temperature | 320℃ | 320'℃ | |

Required nitrogen concentration | 99.999% | 99.999% | |

Nitrogen consumption (single tin furnace) | 25L/Min | 25L/Min | |

positioning accuracy | ±0.075mm | ±0.075mm |

AOI module (optional)

AOI module (optional)During automatic inspection, the machine automatically scans the PCB through the camera, collects images, compares the tested solder joints with the qualified parameters in the database, after image processing, detects solder joint defects, and displays/marks the defects through the display or automatic identification. For repair by maintenance personnel.

Repair after welding

Repair after welding

Application industries and fields

Application industries and fieldsAutomotive electronics, aerospace science and engineering, medical electronics, precision 3C, and other high-demand welding occasions.

Company:Dongguan Zhibang Electronics Co. LTD

Adrress:Floor 15, Yuchang Building, No. 15, Dongyi Lane, Zhongfu Street, Shaguan District, Changan Town, Dongguan City

South China Sales Company: Chengdu Xuanxiang Technology Co., Ltd

Company Address: Room 34F02, Building 2, Shudu Center, Tianfu Second Street, High tech Zone, Chengdu City

Phone: 028-83223255

Fax: 028-8322010

Copyright 2021 Dongguan Zhibang Electronics Co. LTD All rights reserved 粤ICP备14008616号