0769-85317767

Products center

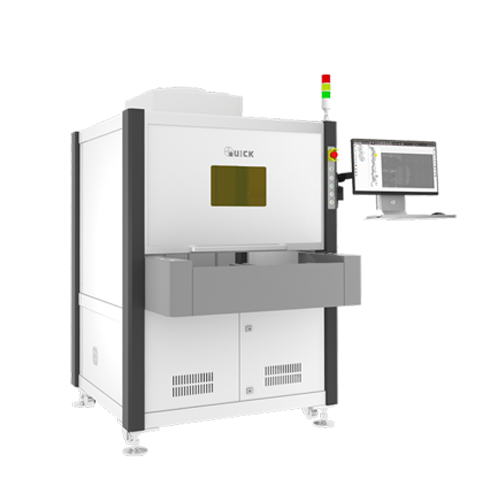

Features

Features0 Flux: No flux is involved, and the pad does not need to be cleaned after soldering.

0 Thermal pressure: Molten tin is sprayed to the pad to avoid thermal pressure during soldering.

Solder quantification: The automatic solder ball feeding method is adopted, with high consistency, which is especially suitable for occasions that require extremely high tin consistency.

Nitrogen protection: Equipped with a nitrogen generation module to protect the entire welding process.

High-efficiency and high-quality: workpiece visual automatic positioning, welding independent and parallel work, the efficiency is increased by more than 2 times.

Safety protection: safety grating, safety door, protection switch, laser protective glass, software and hardware design, implement all-round protection for operators.

Low thermal diffusion: Concentrated heating area, extremely short welding time, especially suitable for high-end precision micro-welding occasions such as fine pins and small spacing.

Company:Dongguan Zhibang Electronics Co. LTD

Adrress:Floor 15, Yuchang Building, No. 15, Dongyi Lane, Zhongfu Street, Shaguan District, Changan Town, Dongguan City

South China Sales Company: Chengdu Xuanxiang Technology Co., Ltd

Company Address: Room 34F02, Building 2, Shudu Center, Tianfu Second Street, High tech Zone, Chengdu City

Phone: 028-83223255

Fax: 028-8322010

Copyright 2021 Dongguan Zhibang Electronics Co. LTD All rights reserved 粤ICP备14008616号