0769-85317767

Products center

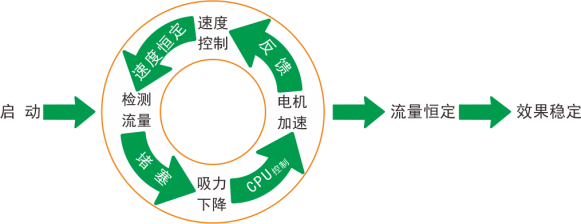

1. Intelligent flow control: The closed-loop control of flow ensures constant suction and saves more consumables.

2. Intelligent peripherals (such as soldering robot/smart soldering station) can control the work and sleep of the purification system, which is more energy-efficient.

3. Intelligently control the speed of the brushless motor, effectively improving the life of the motor.

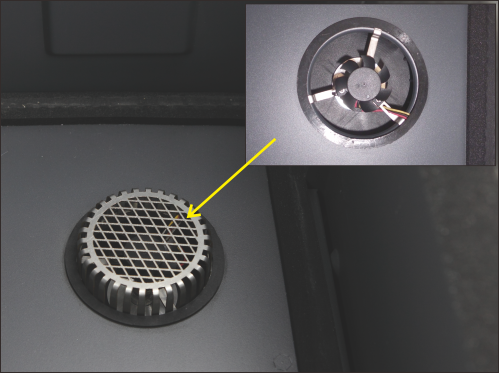

4. Unique vortex wind wheel design, stronger suction.

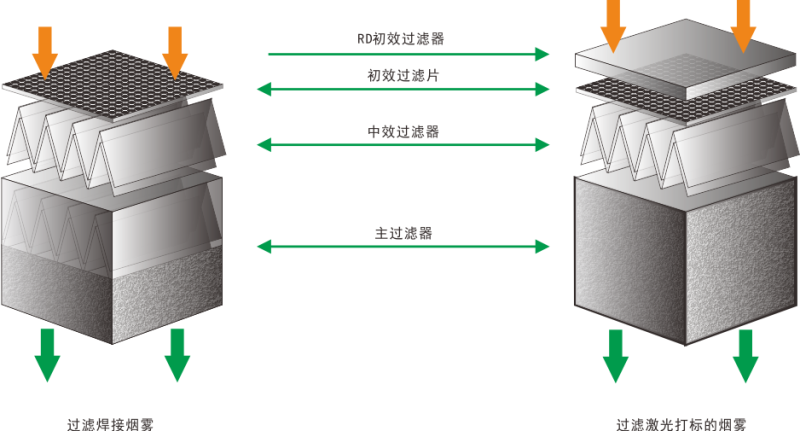

5. Split filter design, the life of the filter element is prolonged, and the cost of consumables is lower.

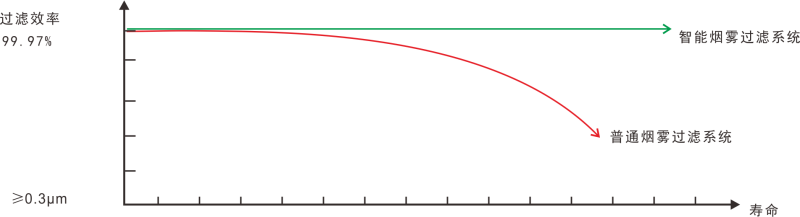

—— Through the closed-loop control of the flow rate, the suction is kept constant and consumables are saved ——

—— A new flow sensor is added to control the motor speed in real time to ensure constant flow and stable filtering effect ——

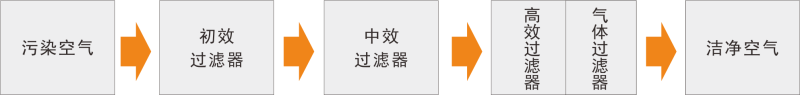

First, harmful smoke passes through the primary filter to filter out larger particulate matter;

Then it passes through a medium-efficiency filter and a high-efficiency filter. It filters particles larger than 0.3 microns from the airflow with an efficiency of 99.97%. This filter is a fiberized glass filtration system.

This process is mainly a physical process.

The other part uses a gas filter to purify the air. This process is mainly a process of physical and chemical interaction.

The gas filter is mainly aimed at finer particles and volatile organic compounds and other gases, using the physical adsorption characteristics of activated carbon and the cooperation of chemical materials to complete the harmless treatment of the gas.

● The traditional ducted fan directly discharges polluted air to the outdoors, causing pollution to the outdoor environment, and at the same time, it does not meet environmental protection requirements.

● Traditional ducted exhaust will discharge indoor air-conditioning or heating to the outdoors at the same time, usually up to hundreds of thousands of cubic meters per hour, causing overloading of air-conditioning refrigeration equipment or heating equipment, and invisible energy waste, cracking smoke The purification system belongs to indoor circulation.

● The ducted exhaust is fixed installation, cannot be moved, and is not suitable for the re-layout adjustment of the production line.

● The ducted exhaust is a rated power motor, which is responsible for the overall operation of the entire factory and workshop. It cannot be independently switched for the designated production line. It is always working at full power and energy is wasted.

● The traditional pipeline type, after using for a period of time, causes the smoking effect to be discounted, the pipeline accumulates a lot of dust in the later stage, it is difficult to clean the sticky flux, etc., and there are certain safety risks.

Smart smoke filter system | Common smoke filtering equipment on the market | |

flow | The flow rate is constant, and the strong suction and filtering effect are continuously maintained. | The suction power is declining, and the filtering effect continues to deteriorate. |

cost | Intelligent flow control and split design ensure a long service life of the filter element. | The filter life is average. |

Online | Smart peripherals can control the work and sleep of the purification system, which is more energy-efficient and convenient. | The smoking device needs to be controlled separately, and the operation is not convenient. |

life | The brushless fan is monitored by sensors, the speed is intelligently adjusted, the noise is low, and the life is long. | Ordinary fans are noisy and have been in a high-speed and unstable working state, with short life span. |

● Soldering iron welding station

● Tin furnace, wave soldering, reflow furnace

● Laser welding, engraving, marking, cutting

● Chemical laboratory, medical treatment, beauty, etc.

Model | QUICK 6611 | QUICK 6612 |

Number of stations | 1 | 2 |

Static pressure | 2400 Pa | 2800 Pa |

System flow (including filter device) | 100 m³/h | 2*100 m³/h |

Filtration efficiency (0.3 microns) | 0.3 micron 99.97% | 0.3micron 99.97% |

power | 120 W | 250 W |

noise | < 60dB | < 65dB |

Voltage | AC 220V | AC 220V |

Dimensions | 420* 230*430*mm | 470*230*500*mm |

Online function | Have | Have |

Flow controller | Have | Have |

External controller | intelligent control | intelligent control |

weight | approximately13.4kg | approximately15.5kg |

Company:Dongguan Zhibang Electronics Co. LTD

Adrress:Floor 15, Yuchang Building, No. 15, Dongyi Lane, Zhongfu Street, Shaguan District, Changan Town, Dongguan City

South China Sales Company: Chengdu Xuanxiang Technology Co., Ltd

Company Address: Room 34F02, Building 2, Shudu Center, Tianfu Second Street, High tech Zone, Chengdu City

Phone: 028-83223255

Fax: 028-8322010

Copyright 2021 Dongguan Zhibang Electronics Co. LTD All rights reserved 粤ICP备14008616号