0769-85317767

Products center

It is very important to choose the correct size and shape of the welding tip. The proper welding tip can make the work more efficient and increase the durability of the welding tip.

The size of the welding tip is directly related to the heat capacity. During continuous welding, the larger the welding tip, the smaller the temperature drop.

In addition, because the large welding tip has a higher heat capacity, relatively low temperatures can be used during welding, and the welding tip is not prone to oxidation, which relatively extends the service life.

Generally speaking, the size of the welding tip should not affect the neighboring components as the standard. Choosing the geometric size that can fully contact the solder joint can improve the welding efficiency

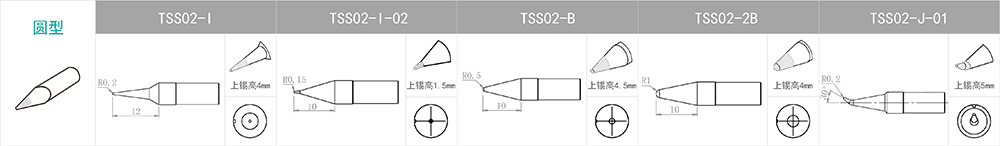

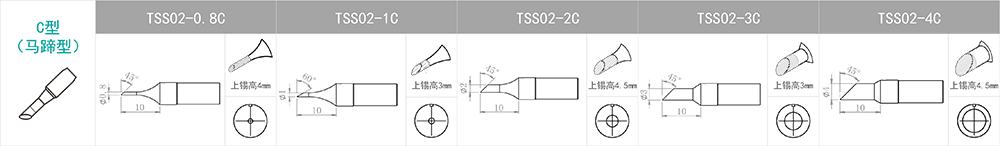

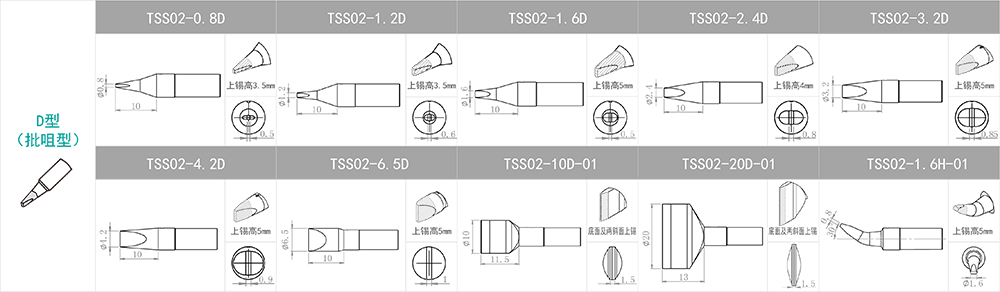

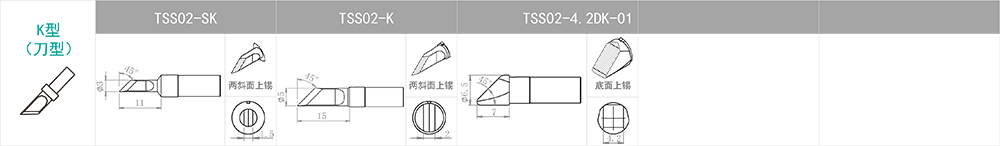

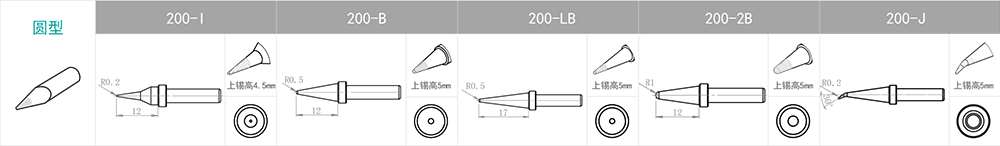

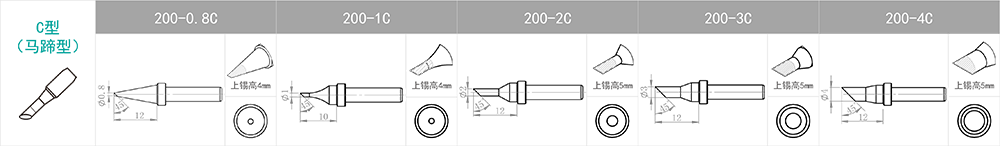

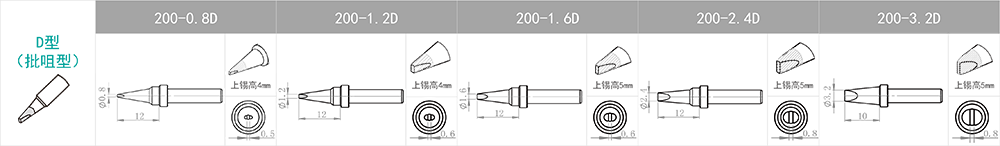

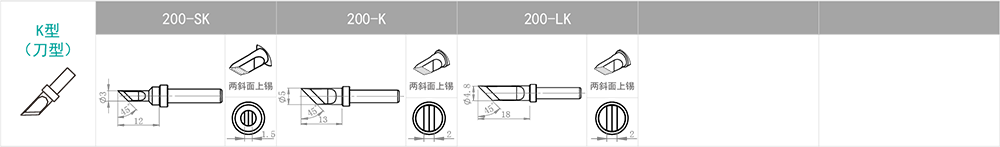

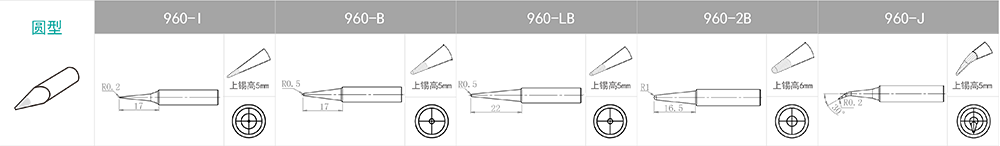

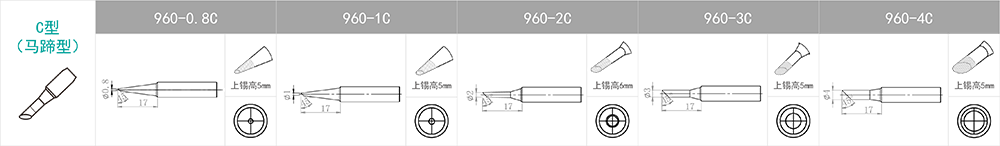

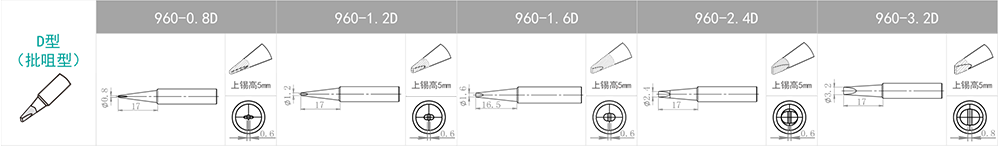

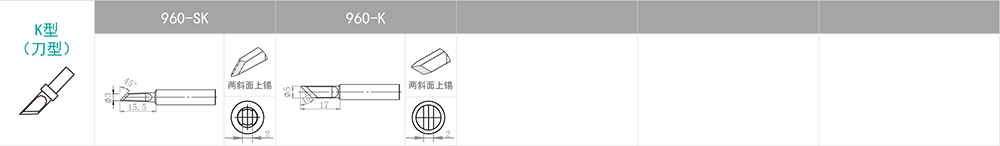

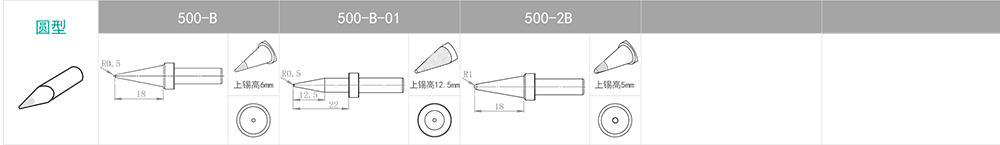

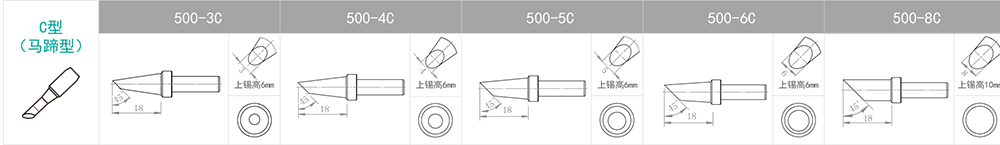

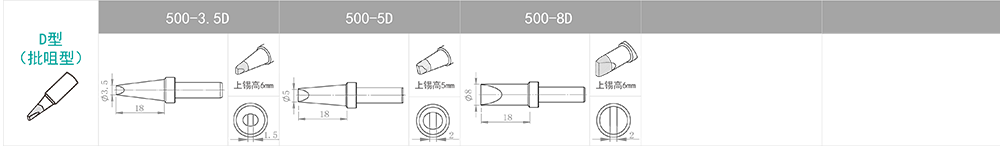

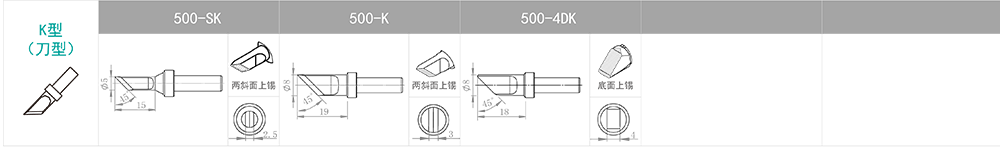

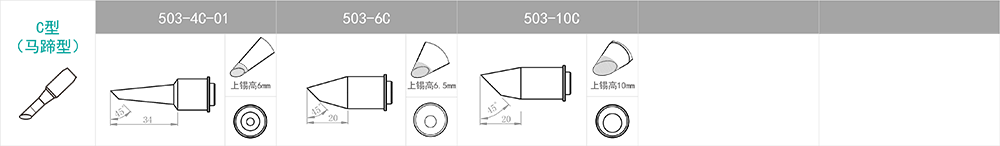

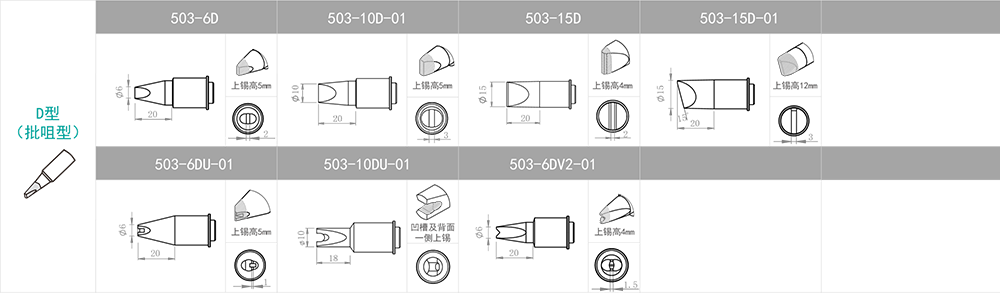

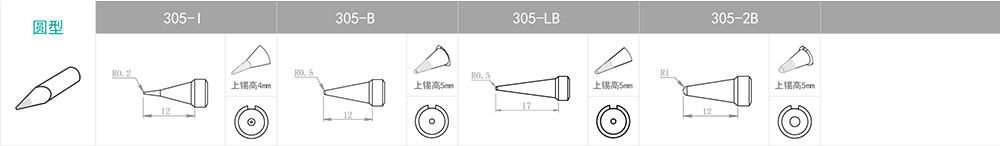

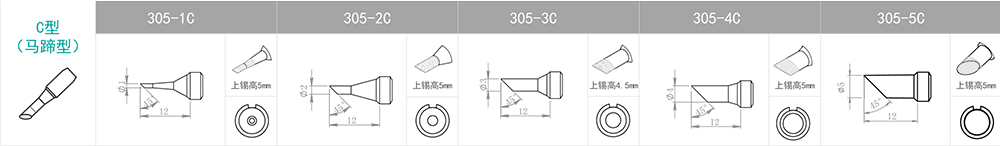

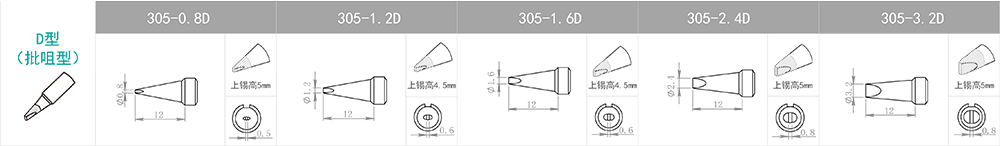

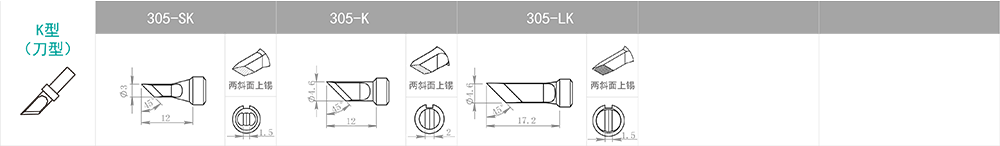

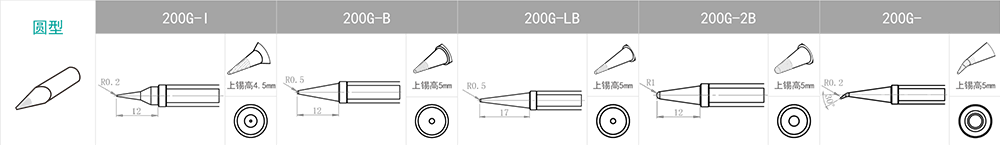

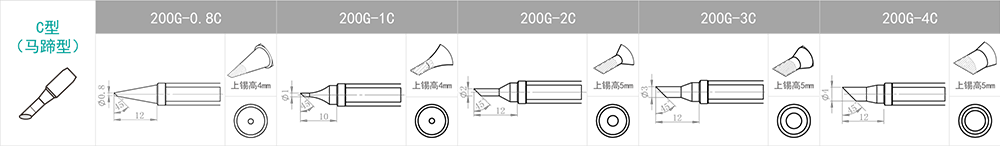

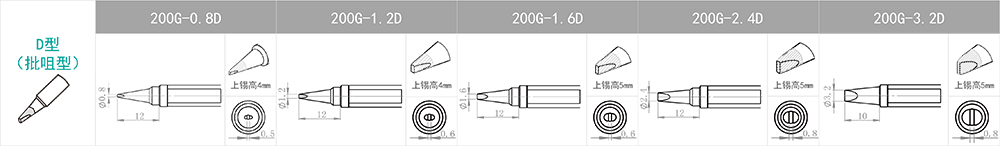

Type I (tip type) | Type B (conical) | D type (one-character batch nozzle) | C type (horseshoe type) | K type (knife type) | |

Features | Tip tip is thin | Type B welding tip has no directionality, The entire tip of the tip can be welded | Use the batch nozzle part for welding | Use the inclined surface of the tip of the tip for welding. Suitable for soldering that requires a large amount of tin. | Use knife-shaped part welding, Either vertical or pull welding can be used. Belong to multi-purpose welding tip |

Application occasion | Suitable for fine welding, Or the welding space is narrow, It can also correct the tin bridges generated when soldering chips | Suitable for general welding, No matter the size of the solder joints, Can use B-type welding tip | Suitable for soldering that requires a large amount of tin. Such as large welding area, thick terminals, Welding environment with large solder joints | The application range of C-type welding tip is similar to that of D-type welding tip. For example, large welding area, thick terminals, Suitable for large solder joints | Suitable for SOJ, PLCC, SOP, QFP, Power supply, grounding components, correction of tin bridge, Connectors and other welding |

Emoticons |

|

|

|

|

|

● When using a new welding tip, set 250~280℃ to tin protection for the welding tip.

● Correctly select the proper welding tip size according to the size of the welding spot.

● To prevent oxidation of the soldering tip, apply a layer of fresh solder before putting it back into the soldering iron stand.

● The cleaning sponge should not have too much water, which can make the welding tip get a good cleaning effect and avoid the rapid cooling of the welding tip; using a non-wetting cleaning sponge will damage the welding tip and cause no tin.

● After the welding tip is improperly oxidized, do not clean the surface coating by grinding. Please use a small metal wire or resurrection paste to clean the welding tip at low temperature (250-280℃).

● Do not apply gravity to the solder tip during soldering and avoid using tin on the same place.

● Try to use low temperature welding. Generally, the welding temperature is controlled at 320~380℃. If you need to set a high temperature to weld, please analyze whether the selection of welding station and welding tip match

|

|

|

|

|

|

|

氧化发黑 | 海绵清洁 | 金属幼丝清洁 | 焊咀加锡保护、光亮如新 | |||

Company:Dongguan Zhibang Electronics Co. LTD

Adrress:Floor 15, Yuchang Building, No. 15, Dongyi Lane, Zhongfu Street, Shaguan District, Changan Town, Dongguan City

South China Sales Company: Chengdu Xuanxiang Technology Co., Ltd

Company Address: Room 34F02, Building 2, Shudu Center, Tianfu Second Street, High tech Zone, Chengdu City

Phone: 028-83223255

Fax: 028-8322010

Copyright 2021 Dongguan Zhibang Electronics Co. LTD All rights reserved 粤ICP备14008616号